Founded in 2010 in Sainte-Croix, Switzerland, at the heart of the miniature and automation industry, IKRtech specializes in the design and production of advanced custom electric motor devices. The company brings extensive expertise to this field, delivering tailored solutions to leading companies across various industries, all while adhering to the highest Swiss quality standards. Each custom solution is crafted to enhance performance, minimize size and weight, and achieve low energy consumption, underscoring the company’s commitment to environmental sustainability.

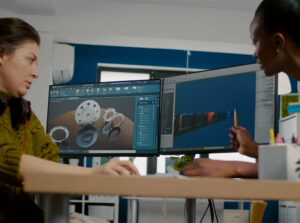

We enhance customer’s specification and design solutions.

Capability to deliver first prototype or small series within 10/14 weeks.

Advise customer’s solution selection, industrialization, testing of the solution.

Customization

The application should not adapt

to the actuator but rather actuator

should adapt to the application

“Jamal Tbatou, CEO”

Founded in 2010 in Sainte-Croix, Switzerland, IKRtech has established itself as a leader in the miniature and automation sectors, specializing in the design and production of custom advanced electrical motor devices. With over 15 years of accumulated expertise, we have successfully delivered tailored solutions to prominent organizations across diverse industries. Our commitment to excellence is anchored in the rigorous quality standards synonymous with Swiss manufacturing, ensuring that every product consistently meets the highest expectations for performance and reliability.

At IKRtech, customization and quality are the cornerstones of our business. These priorities will remain unwavering as we move forward. Guided by a philosophy of zero defects and engineering precision, each bespoke solution we create is designed to optimize performance, reduce size and weight, and minimize energy consumption—all while promoting environmental sustainability. This approach not only fulfills client demands but also aligns with global initiatives for eco-friendly practices.

We are proud of our contributions to cutting-edge technology sectors, where our motors have been integral to major projects, including space missions to Jupiter and advanced semiconductor equipment. Our custom motor designs, paired with the hallmark quality of Swiss engineering, place us at the forefront of innovation, enabling us to consistently deliver results that surpass customer expectations. Our unwavering focus on quality and performance fosters long-lasting client relationships built on trust and satisfaction.

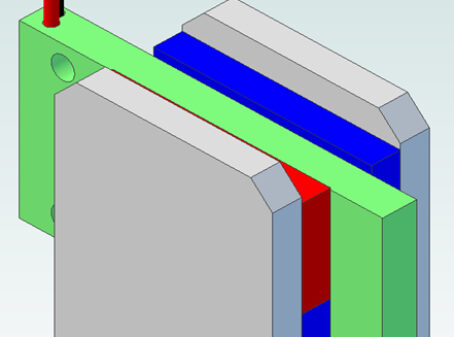

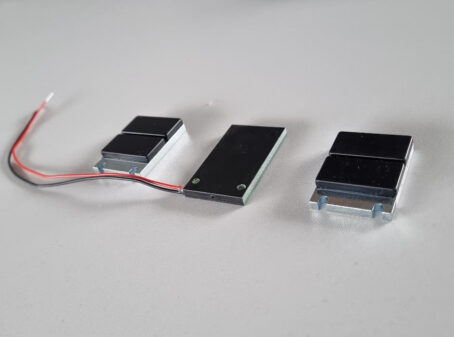

IKRtech’s custom linear motors, available in cylindrical and flat configurations, represent a significant advancement in motion control technology, offering versatile solutions for a broad range of applications. These motors excel in delivering direct linear motion with exceptional precision, even in confined spaces and under demanding conditions, making them indispensable across various industries. By leveraging state-of-the-art Swiss manufacturing, we design motors that not only optimize operational efficiency but also reduce energy consumption, aligning with global sustainability efforts. Our compact, high-performance designs tackle the challenge of minimizing energy and material use without compromising on performance. Beyond speed and precision, our motors are built for durability, capable of withstanding extreme temperatures up to 200 degrees Celsius—a feature that has earned widespread recognition across multiple sectors.

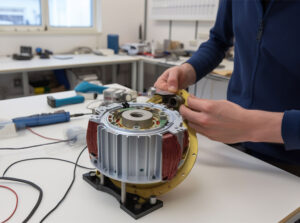

IKRtech’s torque motors play a crucial role in a wide range of applications, delivering exceptional torque and precision even in demanding conditions. Engineered for advanced design and efficiency, the company’s brushless motors and stepper motors operate effectively at lower RPMs, ensuring impressive accuracy even amid significant temperature fluctuations. This capability makes them highly sought after in industries like manufacturing and robotics, where reliability and high performance are essential. IKRtech’s expertise in Swiss-engineered electric motors, designed for high torque output at low to moderate speeds, underscores its leadership in custom direct drive technology, enabling the development of tailored drive solutions to meet the rigorous demands of various sectors.

As a leader in custom direct drive technology, IKRtech is dedicated to delivering bespoke drive system designs that meet the highest industry standards. The company specializes in designing and manufacturing direct drive motors, stages, positioning systems, and precision components, serving a wide range of applications. IKRtech’s commitment to continuous innovation drives the creation of cutting-edge products that significantly boost the productivity and reliability of manufacturing, testing, and inspection systems, ultimately enhancing operational efficiency.

IKRtech’s innovative approach to developing torque motors and direct drive systems consistently meets, and often exceeds, client expectations. Through a focus on precision engineering and high-performance standards, the company ensures that its products withstand the toughest environments. This dedication to quality and performance has established IKRtech as a trusted partner for industries that demand reliable and robust motor solutions, further cementing its reputation as a pioneer in custom direct drive technology.

The IKRtech’s motion controller enhances the overall product lineup by delivering exceptional precision, force, and motion control. This comprehensive turnkey solution seamlessly integrates the electronic driver with IKRtech’s custom motors, ensuring optimal compatibility and operational efficiency. By focusing on the unique requirements of each client and application, IKRtech consistently meets—and often exceeds—expectations, solidifying its reputation as a reliable partner in developing high-performance drive systems tailored to the specific needs of diverse industries.

By incorporating the IKRtech motion controller, the product offering is greatly enhanced, showcasing advanced precision, force, and motion control capabilities. This integration leads to a fully integrated turnkey solution that harmoniously combines the electronic driver with IKRtech’s tailored motors, ensuring exceptional compatibility and performance standards. IKRtech’s commitment to understanding the unique needs of each client and application allows the company to not only fulfill but often exceed client expectations, thereby establishing itself as a dependable partner in the design of high-performance drive systems that cater to the specific needs of various sectors.

The inclusion of the IKRtech motion controller markedly improves the overall product suite by providing enhanced precision, force, and motion control abilities. This integration results in a comprehensive turnkey solution that effectively unites the electronic driver with IKRtech’s specialized motors, ensuring superior compatibility and performance. By concentrating on the individual requirements of each client and application, IKRtech not only satisfies but often goes beyond expectations, thereby solidifying its status as a trusted ally in the development of high-performance drive systems specifically designed for the diverse needs of multiple industries.

The IKRtech team is committed to enhancing specifications and designs that cater specifically to the unique needs of each client. This dedication ensures that every project emphasizes Swiss quality and innovation, delivering tailored solutions that consistently exceed customer expectations. By prioritizing client satisfaction, IKRtech fosters strong partnerships that drive mutual success throughout the development process.

IKRtech is focused on delivering prototypes and initial production runs within a period of 12 to 14 weeks, underscoring its strong commitment to efficiency and prompt execution. This dedication to swift delivery is vital for clients eager to introduce their concepts to the market in a timely manner. The company’s optimized processes and proficient project management techniques play a significant role in achieving this rapid turnaround, ensuring that clients can progress with their projects without facing unnecessary delays.

Armed with state-of-the-art software and simulation tools, IKRtech excels in motor sizing, modeling, design, and calculations, which are critical for effective prototyping. The research and development team is instrumental in this endeavor, concentrating on expediting development while upholding stringent quality standards. Furthermore, the company’s extensive inventory of varied materials and substantial machine tool capacity facilitates quick fabrication, while its laboratory and manufacturing facilities are equipped with testing capabilities that bolster comprehensive prototyping efforts.

At the conclusion of the development and prototyping phases, IKRtech is dedicated to preparing comprehensive technical and manufacturability documentation. This ensures a smooth transition to production scaling while maintaining the Swiss quality standards that distinguish the company. By adhering to these rigorous standards, IKRtech provides its clients with a competitive edge in the marketplace.

IKRtech’s manufacturing team, along with trusted vendors, rigorously follows established working and testing protocols. This strict compliance is crucial for upholding the high-quality standards that customers expect. By meticulously following these procedures, IKRtech consistently meets—and often exceeds—client expectations.

IKRtech’s focus on both quality and efficiency not only enhances its production capabilities but also strengthens its reputation for excellence. The integration of thorough documentation and stringent testing protocols enables the company to scale operations effectively while preserving product integrity. This unwavering commitment to quality assurance positions IKRtech as an industry leader, fostering trust and loyalty among its customers.